Mechanisms of membrane fouling and advanced membrane cleaning

Fouling of various origins – organic, colloidal, mineral or biological – is still a limiting factor in the large-scale application of membrane technology for water production. For example, current practice in RO desalination is the periodic cleaning of membrane elements, using a variety of chemicals used to target different types of foulants present. Such cleaning-in-place (CIP) methods are often insufficient for flux restoration; moreover, they result in significant down-time of the plant and, most importantly, reduce the life-span of the membrane.

Our activities span a range of problems and fundamental questions related to fouling minimisation – from understanding what are the important parameters leading to fouling for a given system, to what strategies can be used for removing accumulated foulants. Some of the current projects are outlined below:

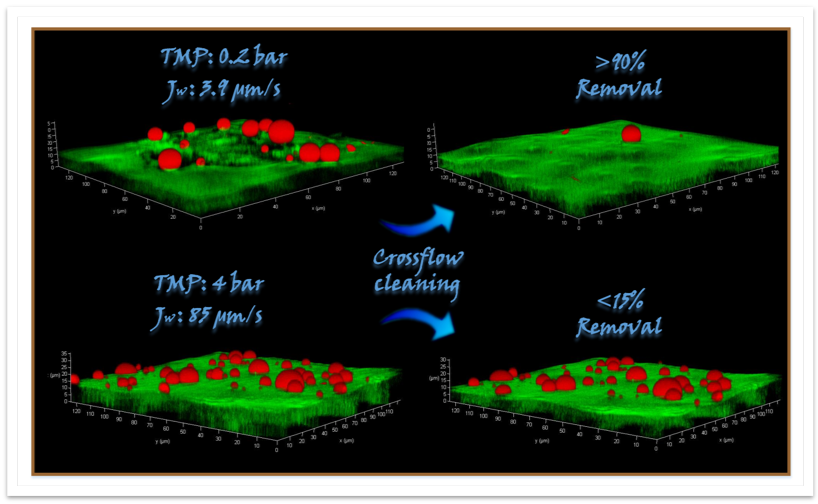

Membrane separation of oil-water emulsions

Oil/water separation is a challenging process, needed for a number or applications. Most relevant to us, wastewater from oil and gas production often contain stable oil droplets that are tough to remove… membranes do a great job but clog in the process. We use advanced visualisation techniques to measure the deformation and adhesion of oil droplets to membrane surfaces, so that this understanding can translate to better membrane materials and process design.

Publications:

Fux, G., Ramon, G.Z. Environmental Science and Technology, 2017

Polymer brush coatings for membrane fouling resistance

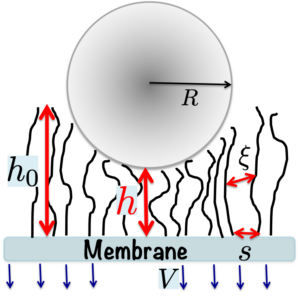

Colloidal deposition onto permeable surfaces

read more here

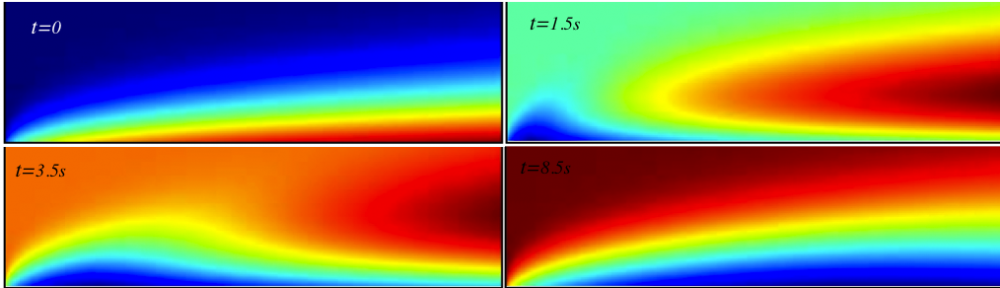

Osmotic backwashing

We are currently investigating a novel fouling countermeasure for salt-rejecting membranes – osmosis-assisted cleaning. This method enables the reversal of the permeation direction by introducing a pulse of a high salinity ‘draw’ solution and establishing a trans-membrane osmotic pressure difference which exceeds the applied hydraulic pressure. It is further hypothesized that the physical drag force imparted by the reversed permeation may not be sufficient in restoring flux once fouling has occurred; in such cases, the chemical composition of the osmotic draw solution must also be considered. Depending on the type of fouling (e.g., organic, colloidal, mineral or biological), each exhibiting differing characteristic interactions with the membrane, tailored osmotic draw chemistry may be best suited for optimal cleaning efficiency. Preliminary experimentation has confirmed this hypothesis for the cleaning of organic-fouled RO membranes. More importantly, flux restoration using osmotic backflushing has been observed to be comparable with that achieved by the use of a chemical cleaning protocol. Future experimental studies will be devoted to further testing this hypothesis on specific foulants commonly encountered in applications such as seawater, brackish water and wastewater. Beyond the specific chemistry of the selected draw solution, optimization of various operational parameters will be performed, e.g. concentration, duration and frequency.

Publications:

-

-

-

-

- Dynamics of an osmotic backwash cycle

Ramon, G., Agnon, Y., Dosoretz, C., Journal of Membrane Science, 2010 - Osmosis-assisted cleaning of organic-fouled seawater RO membranes

Ramon, G.Z., Nguyen, T.-V., Hoek, E.M.V., Chemical Engineering Journal, 2013

- Dynamics of an osmotic backwash cycle

-

-

-